Optimizing vehicle dynamics: sensors and systems for mobility and motorsport.Electromechanical joining: making production more cost-effective and transparent.Quality assurance for medical technology: what is important?.Committed to people and the environment.Organizational structures of the Kistler Group and Corporate Governance.Wheel force measurement with KiRoad Performance.Optical sensors | optosensors and inductive proximity switches.Products for the KiDAQ data acquisition system.Dynamic brake testing and measurement of speed.

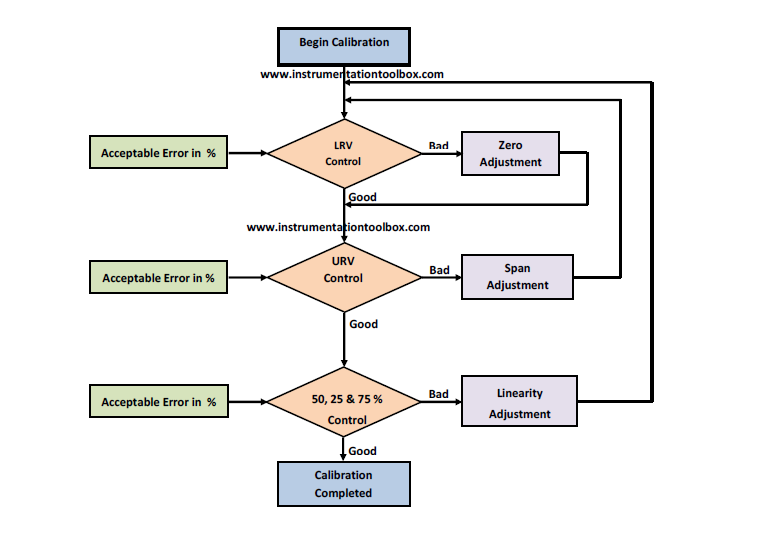

#Smart tool calibration software

Data management software for traffic monitoring.Benefits of quartz piezoelectric technology for Weigh In Motion (WIM) systems.Optical in-line inspection systems – imaging.Optical measurement and sorting machine with feeder robot.Rotary indexing testing and sorting machines.Testing and sorting machines – bulk material small parts.Measurement and sorting machines for mass-produced parts.Optical measuring, inspection and sorting machines – imaging.Solutions for monitoring and control in semiconductor manufacturing.Semiconductor production monitoring through integrated measurement technology.Force measurement for semiconductor manufacturing.Services – process monitoring for medical device manufacturers.Servo presses for assembly and testing of medical devices.Process monitoring in medical device assembly and testing.Monitoring of medical device plastic injection molding.Medtech – quality assurance for manufacturing.Measuring technology – customized solutions.Threaded fastener tightening process monitoring.Process inspection in fastener assembly.Fracture splitting – process monitoring.Forming process monitoring for quality assurance.Joining process monitoring for quality assurance.Joining Competence Center: test workstation for joining processes.Servo press | Electromechanical joining systems.Composite – quality assurance by RTM process monitoring and control.Injection molding – quality assurance based on process monitoring.Cavity pressure measurement in injection molding.Friction testing and testing of efficiency at end-of-line test stands.Industrial signal conditioning for smart factory.Tool monitoring with cutting force dynamometers.Analysis of cutting forces and process optimization with dynamometers.Tool development and tool assessment through cutting force measurement.Dynamometers for cutting force measurement.Hydrodynamic testing solutions for maritime and naval applications.Maritime and naval measurement technology.

0 kommentar(er)

0 kommentar(er)